45 Lb. Capacity Poly Multi-Purpose Applicator

The 45-lb. capacity Poly Stainless Multi-Purpose hopper allows you to apply fertilizer, granular chemical, seed and small grains. Includes four each, full-rate black metering wheels for granular chemicals and small seeds like alfalfa, canola, etc.; red metering wheels for fertilizer and small grains such as oats, wheat, barley and rice; yellow high-output metering wheels for fertilizer. Operator can easily configure applicator from one to four outlets by simply sliding out the shaft and removing or installing metering wheels and cups. For unused outlets, blanking plates are provided to seal outlet openings.

Equipped with a stainless steel metering housing, a standard bolt-in agitator is included to assist in product flow. The positive displacement design means that when the metering stops, all flow stops. And, if the unit is ground-driven, the metering compensates for the ground speed. A U-frame bracket is included to allow for easy surface mounting. The 3" x 14" bracket comes with 1/2" pre-drilled holes and slots. For easy clean-up, a snap-tite clean out plug can be quickly removed allowing material from the hopper to empty.

Drive options include a ground-drive or 12-volt electric motor. Rate control sprocket package is required to set application rates and optional connector tubes are available to connect multiple hoppers together when they are mounted in-line. A hopper extension providing 30 lbs., of capacity is available as an option.

45 Lb. Capacity Poly Stainless Multi-Purpose Applicator

Features

- 45-lb. translucent poly hopper (60-lb. per cu. ft. density)

- Optional 30-lb. capacity extension

- Stainless steel housing to resist corrosion

- Four each: Red (F) metering wheels, Black (C) metering wheels; Yellow (V) metering wheels

- Internal agitator

- See-through weather-guard shield protects metering output

- Positive shutoff when metering stops

- Speed compensated if ground-driven

- Fertilizer fed under metering wheel, then down tube

- U-frame mounting bracket with pre-drilled 1/2" holes and slots

- Translucent lid with strap latches

Drive Options

User will need to provide chain and drive sprocket to hopper input shaft from the parent implement's live shaft to provide 2 or 4 rpm to the Gandy input shaft depending on chemical rate, or purchase the Gandy ground drive package. If non-speed compensation is required, user may select a 12-volt drive.

Sprocket Package

Rate control sprocket package is required to set individual hopper rates and can control multiple hoppers when mounted in-line.

Connector Tubes

If multiple hoppers are mounted in-line, connector tubes will be needed to connect each hopper's drive and agitator shafts.

Tubing

Requires 1.5-inch ID tubing with hose clamps to secure tubing to outlets

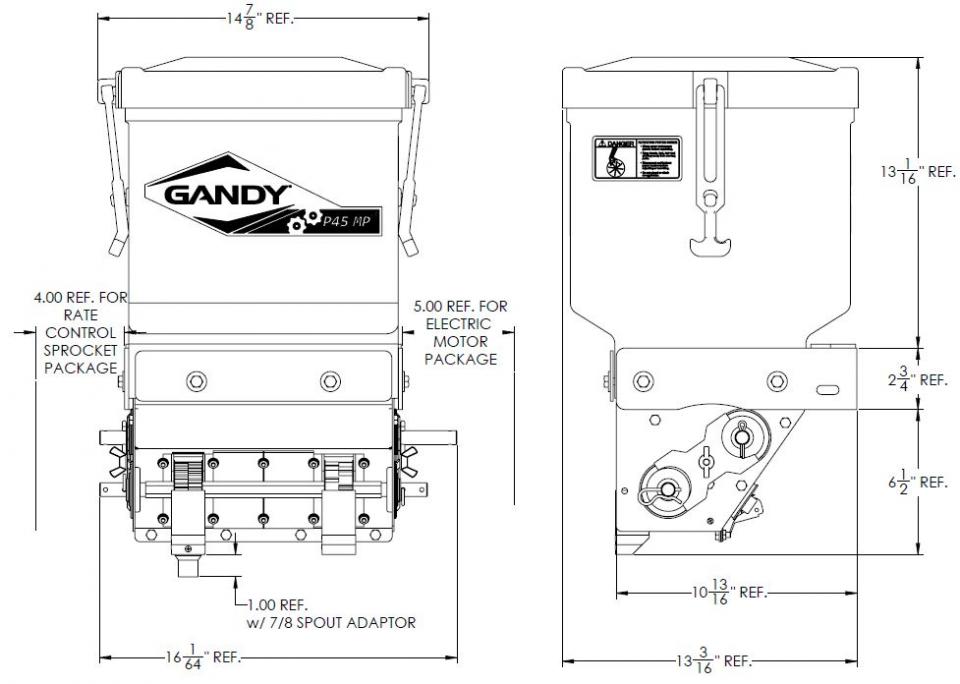

Dimensions

How many outlets can be configured on each individual applicator?

Each unit can have from one to four outlets depending upon your application. The unit is shipped without the metering cups or wheels in place, allowing you to configure the applicator to your needs.

If I don't use all four outlets, how do I block off an outlet?

There are three blank plates included with each applicator. Instead of placing a metering cup over the opening, you simply bolt on the supplied blank plate to cover the opening (see operator's manual for step-by-step instructions).

How do you go about installing the metering cups and wheels?

Simply remove the hairpin cotter and slide the shaft back. Install the metering cup(s) onto the unit and place the metering wheel(s) along with the required wear plates into the metering cup. Slide the shaft through the opening and lock the shaft into position with hairpin cotter (see operator's manual for step-by-step instructions).

What is the function of a wear plate?

Wear plates go on the outside of the metering wheels to prevent binding caused by material going between the metering cup and the metering wheel.

Why do I need to install "hole closure halfs" into each metering cup when using black metering wheels?

Hole closure halfs are placed directly behind a black metering wheel in order to limit the amount of material coming in contact with the metering wheel. Black metering wheels are typically used with granular chemicals and small seeds which can work there way between the outside edge of the metering wheel and cup causing the metering wheel to bind.

What are the spout adaptor's used for?

Spout adaptor's should only be used with black metering wheels when applying granular chemcial and small or fine seeds for lower application rates. When using a spout adaptor, 7/8" tubing is required.

Do I need to install the optional agitator that came with the applicator?

The agitators need only be installed when using material that is bulky and normal vibration from moving is not enough. Typically, used only in fertilizer applications.

Why is rate control sprocket package required?

A rate control sprocket package contains 12 sprockets ranging in size from 8-tooth to 34 tooth sprockets. It also includes two 16-tooth sprockets for a 1:1 ratio. By using the appropriate combination of sprockets, you achieve the proper metering shaft RPM giving you the desired application rate. Note: If using more than one multi-purpose applicator and connecting them with drive tubes, only the last hopper in the row will need a rate control sprocket. However, if you place multiple units on the parent implement and they are not connected, you will need a separate rate control package and drive for each applicator.

What are connector drive tubes used for?

Connector drive tubes are used to join the metering shafts of multiple applicators together when they are mounted in-line. This allows the operator to use just a single rate control package and one drive system. Note: if operator chooses to use optional agitators, a connector drive tube will be required to connect each metering shaft and another drive tube used to connect the agitator shafts.

What are black metering wheels used for?

For granular chemicals and small seeds such as alfalfa, rye, canola, etc.

What red metering wheels used for?

Fertilizer and small grains such as oats, wheat, rice, barley, etc.

What are yellow metering wheels used for?

Primarily for fertilizer. Yellow metering wheels output approximately 1.5 times more than red metering wheels. Caution should be exercised so that you do not exceed the rate capacity of the metering cups and tubing resulting in blockage.